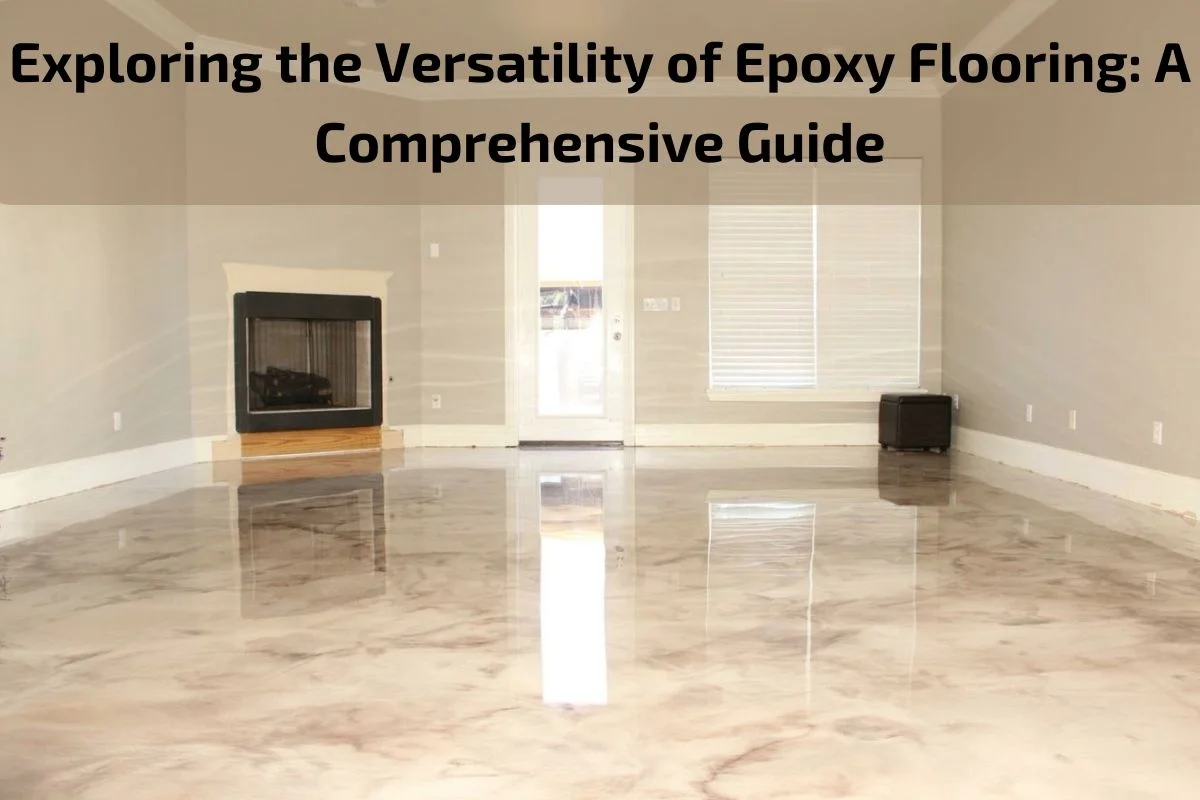

Epoxy flooring has emerged as a popular choice for both residential and commercial spaces, offering a unique blend of durability, versatility, and aesthetic appeal. From sleek and modern industrial settings to vibrant and creative residential interiors, epoxy flooring has transformed the way we think about flooring solutions.

In this comprehensive guide, we will delve into the versatility of epoxy flooring, exploring its various applications, benefits, and considerations for installation and maintenance. Whether you’re considering epoxy flooring for your home, garage, showroom, or commercial space, this guide will provide valuable insights to help you make informed decisions and unleash the full potential of epoxy flooring in your design projects.

Brief Overview of Epoxy Flooring

Epoxy flooring is a versatile and durable flooring solution that has gained popularity in both residential and commercial settings. It is composed of a combination of epoxy resin and a hardener, which when mixed together, chemically react to form a rigid plastic material. This material bonds tightly to concrete substrates, creating a seamless and highly resilient surface.

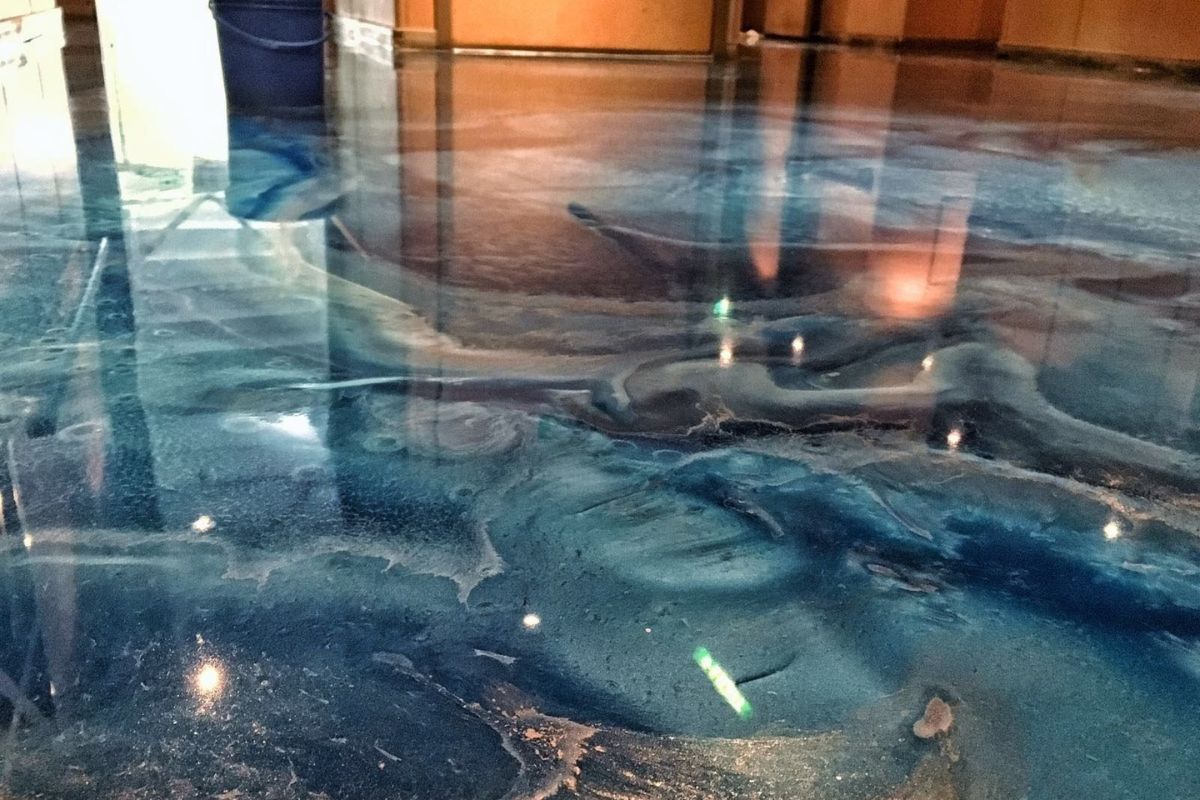

Epoxy flooring is known for its exceptional durability, resistance to stains, chemicals, and abrasion, making it ideal for high-traffic areas such as garages, warehouses, and industrial facilities. It also offers a wide range of design options, including solid colors, metallic finishes, and decorative flakes, allowing for customization to match any aesthetic or design scheme.

One of the key advantages of epoxy flooring is its ease of maintenance. It can be easily cleaned with mild detergents and water, and its seamless surface prevents the accumulation of dirt, dust, and bacteria. Additionally, epoxy flooring is resistant to moisture, making it suitable for areas prone to spills or humidity.

Overall, epoxy flooring is a cost-effective, durable, and aesthetically pleasing flooring solution that offers numerous benefits for residential, commercial, and industrial applications. Its versatility, durability, and ease of maintenance make it a preferred choice for a wide range of projects and environments.

Advantages and Disadvantages of Epoxy Flooring

Epoxy flooring offers several advantages as well as a few potential drawbacks that should be considered before installation. Here’s a breakdown of the pros and cons:

Advantages:

Durability: Epoxy flooring is incredibly durable and can withstand heavy traffic, impacts, and abrasions, making it ideal for high-traffic areas like garages, warehouses, and industrial facilities.

Chemical Resistance: Epoxy flooring is highly resistant to chemicals, including acids, oils, grease, and solvents, making it suitable for environments where spills and chemical exposure are common.

Aesthetic Appeal: Epoxy flooring comes in a variety of colors, finishes, and decorative options such as metallic flakes and quartz aggregates, allowing for customization to match any design aesthetic.

Seamless Surface: Once cured, epoxy flooring creates a seamless surface that is easy to clean and maintain. Its smooth surface prevents the accumulation of dirt, dust, and bacteria, making it hygienic and easy to sanitize.

Longevity: Properly installed and maintained epoxy flooring can last for many years, providing a long-lasting flooring solution that requires minimal repairs or replacements.

Disadvantages:

Installation Complexity: Installing epoxy flooring requires careful surface preparation and application techniques to ensure proper adhesion and curing. Improper installation can lead to bubbling, peeling, or delamination of the coating.

Slippery When Wet: Epoxy flooring can be slippery, especially when wet. Adding anti-slip additives or texture to the surface can help improve traction and safety, but it’s essential to consider slip resistance in areas prone to spills or moisture.

Vulnerable to UV Exposure: Epoxy flooring may yellow or discolor when exposed to direct sunlight or UV radiation over time. This can be mitigated by applying UV-resistant topcoats or choosing epoxy formulations designed for outdoor use.

Temperature Sensitivity: Extreme temperature fluctuations can affect the performance and longevity of epoxy flooring. In areas subject to temperature variations, thermal expansion and contraction may cause the epoxy to crack or delaminate.

Cost: While epoxy flooring offers long-term durability and cost savings, the initial installation cost can be higher compared to traditional flooring options like vinyl or tile. However, the long-term benefits often outweigh the initial investment.

In summary, epoxy flooring offers numerous advantages, including durability, chemical resistance, and aesthetic appeal, making it a popular choice for a wide range of applications. However, it’s essential to consider potential drawbacks such as installation complexity, slipperiness when wet, and vulnerability to UV exposure before selecting epoxy flooring for your space. Proper installation, maintenance, and consideration of specific environmental factors can help maximize the benefits of epoxy flooring while minimizing potential drawbacks

Comparing Epoxy Flooring with Other Flooring Options

When considering flooring options for your space, it’s essential to weigh the pros and cons of epoxy flooring against other available choices. Here’s a comparison of epoxy flooring with some common alternatives:

Epoxy Flooring vs. Vinyl Flooring:

Epoxy Flooring: Offers superior durability, chemical resistance, and customization options compared to vinyl flooring. However, epoxy flooring requires professional installation and may be more expensive upfront.

Vinyl Flooring: Cost-effective and easy to install, but less durable and prone to scratching and wear compared to epoxy flooring. Vinyl flooring also has limited design options.

Epoxy Flooring vs. Tile Flooring:

- Epoxy Flooring: Provides a seamless, non-porous surface that is resistant to stains, chemicals, and moisture. Epoxy flooring is also more customizable and offers a smoother finish compared to tile flooring. However, epoxy flooring may be more susceptible to UV damage and requires periodic resealing.

- Tile Flooring: Durable and easy to clean, but grout lines can be difficult to maintain and may trap dirt and bacteria. Tile flooring offers more design options and can withstand heavy foot traffic, but individual tiles may crack or chip over time.

Epoxy Flooring vs. Concrete Flooring:

- Epoxy Flooring: Enhances the durability and aesthetics of concrete surfaces while providing chemical resistance and ease of maintenance. Epoxy flooring is available in a variety of colors and finishes and can be customized to suit different design preferences. However, epoxy flooring may require periodic reapplication and is susceptible to UV damage.

- Concrete Flooring: Provides a durable and versatile flooring option, but may require sealing or coating to enhance durability and prevent staining. Concrete flooring is prone to cracking and may require regular maintenance to preserve its appearance.

Epoxy Flooring vs. Hardwood Flooring:

- Epoxy Flooring: Offers superior durability and resistance to moisture, stains, and scratches compared to hardwood flooring. Epoxy flooring is also more affordable and easier to maintain, making it a practical choice for high-traffic areas.

- Hardwood Flooring: Adds warmth and elegance to interior spaces, but requires regular maintenance, including refinishing and resealing. Hardwood flooring is susceptible to scratching, water damage, and UV fading, and may not be suitable for areas prone to moisture or heavy use.

Installation Process of Epoxy Flooring

The installation of epoxy flooring involves several crucial steps to ensure a durable, long-lasting finish. Here’s an overview of the typical installation process:

Surface Preparation:

- The success of epoxy flooring installation largely depends on proper surface preparation. The concrete substrate must be clean, dry, and free of any contaminants, such as dirt, oil, grease, or existing coatings.

- Surface preparation may involve mechanical methods such as shot blasting or grinding to remove surface imperfections and open up the pores of the concrete for better adhesion.

Patching and Repairs:

- Any cracks, spalls, or surface defects in the concrete substrate should be repaired using suitable patching compounds or epoxy mortars. These repairs ensure a smooth and level surface for the epoxy coating to adhere to.

Primer Application:

- Once the surface is properly prepared, a primer coat is applied to enhance adhesion between the epoxy coating and the substrate. The primer helps to seal the concrete and prevent outgassing, which can lead to air bubbles in the epoxy coating.

Epoxy Application:

- After the primer has cured, the epoxy resin and hardener are mixed according to the manufacturer’s instructions. The epoxy mixture is then applied to the prepared surface using a roller, brush, or squeegee.

- Depending on the desired thickness and finish, multiple coats of epoxy may be applied. Each coat must be allowed to cure properly before the next coat is applied.

Optional Decorative Elements:

- For decorative epoxy flooring, such as metallic or flake systems, decorative elements like metallic pigments or colored flakes may be broadcast onto the wet epoxy surface to create desired effects.

- Once the decorative elements are applied, a clear topcoat is typically applied to seal and protect the epoxy system while enhancing its durability and aesthetics.

Curing and Drying:

- The epoxy coating requires sufficient time to cure and harden before it can withstand foot traffic or other loads. Curing times vary depending on environmental conditions and the specific epoxy product used.

- It’s essential to follow the manufacturer’s recommendations for curing and drying times to ensure proper adhesion and performance of the epoxy flooring.

Final Inspection and Touch-Ups:

- Once the epoxy flooring has fully cured, a final inspection is conducted to ensure that the surface is uniform, free of defects, and meets the desired specifications.

- Any touch-ups or repairs needed, such as filling in pinholes or sanding rough spots, are addressed before the flooring is put into service.

Maintaining and Caring for Epoxy Flooring

Epoxy flooring is known for its durability and ease of maintenance, but proper care is essential to ensure its longevity and aesthetic appeal. Here are some tips for maintaining and caring for epoxy flooring:

Regular Cleaning:

- Sweep or vacuum the floor regularly to remove dirt, dust, and debris. Use a soft-bristle broom or a dust mop to avoid scratching the epoxy surface.

- For more thorough cleaning, mop the floor with a solution of mild detergent and warm water. Avoid using harsh cleaners or abrasive materials that can damage the epoxy coating.

Prompt Spill Cleanup:

- Clean up spills and stains promptly to prevent them from penetrating the epoxy surface. Use a soft cloth or paper towel to blot up spills, and then clean the area with mild detergent and water.

- Avoid using acidic or caustic cleaners, as they can dull the epoxy finish and compromise its integrity.

Avoid Sharp Objects:

- Avoid dragging heavy furniture or sharp objects across the epoxy flooring, as they can scratch or gouge the surface. Use furniture pads or protective mats under heavy furniture to prevent damage.

- Place doormats at entryways to trap dirt and grit from shoes, reducing the risk of scratches and abrasions on the epoxy surface.

Prevent Moisture Damage:

- Epoxy flooring is resistant to moisture, but standing water or prolonged exposure to moisture can still cause damage over time. Wipe up spills promptly and ensure proper drainage in areas prone to water accumulation.

- In areas where moisture is a concern, consider using rugs or mats to absorb excess water and protect the epoxy flooring.

Periodic Maintenance:

- Periodically inspect the epoxy flooring for signs of wear, scratches, or damage. Address any issues promptly to prevent them from worsening.

- Depending on the level of traffic and wear, consider applying a fresh coat of epoxy or a maintenance topcoat every few years to restore the finish and extend the lifespan of the flooring.

Avoid Harsh Chemicals:

- Avoid using harsh chemicals, solvents, or abrasive cleaners on epoxy flooring, as they can damage the epoxy coating and compromise its performance.

- If necessary, use pH-neutral cleaners or specialized epoxy floor cleaners recommended by the manufacturer.

Conclusion

In conclusion, epoxy flooring offers a versatile, durable, and aesthetically pleasing flooring solution for a wide range of residential, commercial, and industrial applications. With its exceptional durability, resistance to stains and chemicals, and customizable design options, epoxy flooring has become a popular choice for homeowners, business owners, and facility managers alike.